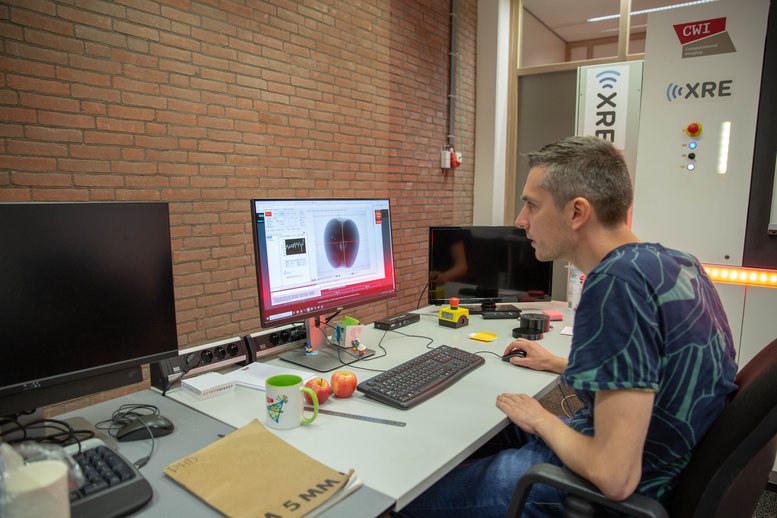

"Goudreinnetten, Kanzi's, Braeburns, all added up, I scanned five hundred apples one by one," says PhD candidate Dirk Schut as if it's the most ordinary thing in the world. The aim of his research: to determine whether you can see if an apple is good or already shows brown spots from the inside. Companies that inspect the quality of food before it goes to the supermarket are very interested in these types of techniques.

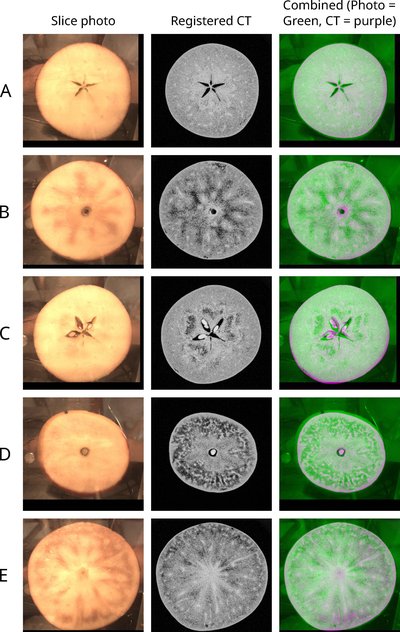

One such company is GREEFA, an industrial partner in Schut's research, which is connected to the Computational Imaging group of CWI. GREEFA makes sorting machines for fruits and vegetables. The sorting is done by using multiple parameters, such as the weight of the fruit and/or photographing it with different wavelengths, such as infrared light. By using image analysis, the bad specimens are filtered out. "The drawback is that you can only view the inside of an apple as a whole," says Schut. "On the CT scans that the FleX-ray creates, you can see every part of the apple in 3D. You can zoom in on any desired spot – for example, on an abnormal one – and see exactly where the discoloration stops."