In 2017, CWI and partners founded the FleX-ray Lab - a custom-made, fully-automated X-ray CT scanner linked to large-scale computing hardware. At the FleX-ray Lab mathematics and computer science meet, combining novel algorithms and a state-of-the-art X-ray scanner. The Computational Imaging group uses this unique facility to develop advanced computational techniques for 3D imaging in collaboration with partners from health care, science, industry and cultural heritage

FleX-ray Lab

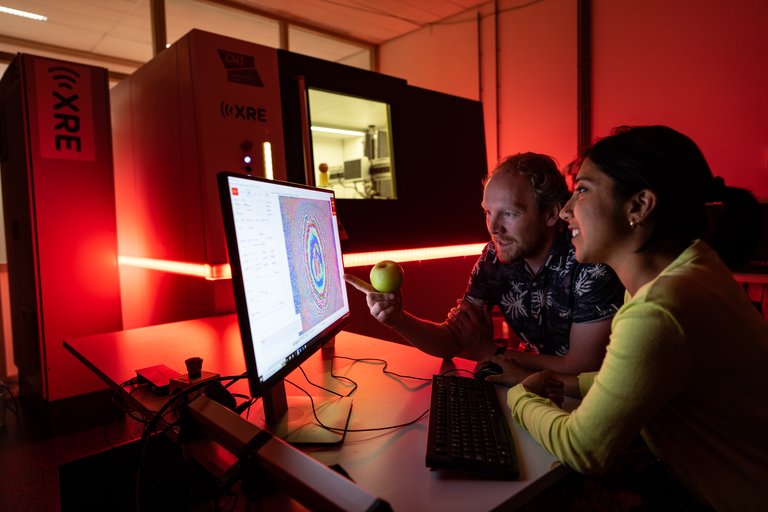

In 2017, CWI and partners founded the FleX-ray Lab - a custom-made, fully-automated X-ray CT scanner linked to large-scale computing hardware.

Look inside an object

With the scanner of this lab, it has been made possible for the first time to look inside objects in 3D during the scanning process and to adjust or zoom in while scanning. This is a revolutionary step forward, comparable to the transition from the old fashioned film roll to digital photography. Thanks to realtime data processing and adjustment the scanner is able to retrieve more useful information from the scans -faster and with less harmful X-ray dose- than allowed by current technology. At the moment objects have to be scanned for a long time and can only be reviewed after.

Realtime adaptive imaging

The FleX-ray Lab embodies our vision on real-time, adaptive imaging. By transforming the linear imaging pipeline to a circular one, feedback from the expert can be incorporated directly in the scanning process. By coupling a versatile micro-CT scanner with high-end computational facilities, we can bridge the gap between theory and practice. Our scanner allows us to emulate various scanning geometries, including conveyor belt setups, and modern medical (helical) scans.

Making the invisible visible

The number of application domains possible, is endless. The new techniques can be used for medical imaging, quality control in the food industry and restauration of antique masterpieces. Partnerships with for example Rijksmuseum, Naturalis and Meyn food processing technology have already been established. With the scanner little cracks in antique vases can be tracked, or pieces of bone that have remained inside chicken filet that would not have been noticed otherwise. A sustainable and efficient quality control is of the utmost importance to the manufacturing industry. At this moment quality control often takes place after the production process, whereby errors in the process cannot be fixed anymore. By already looking into the objects during the manufacturing process, errors can be detected in realtime, resulting in a more sustainable manufacturing process.

Innovation through collaboration

The scanner of the lab has been developed in cooperation with the Flemish company X Ray Engineering (spin-off University of Gent) and contains special detector technology from research institute Nikhef. This technology allows coloured images to be recorded with X-rays. Alongside with the algorithms developed by CWI, the technology makes it possible to detect the separate elements (for example carbon and copper). Another academic spin-off was also involved in the partnership that develops the technology for the FleX-ray lab: the Amsterdam based company ASI (a Nikhef spin-off) develops hardware and software for the spectral detectors.

The Computational Imaging group of CWI is internationally leading in the area of new mathematical image reconstruction techniques. CWI will make the research data and realtime software available as open source.

Contact

Are you interested to learn more about our research, the FleX-ray Lab, or want to collaborate with us? CWI's Computational Imaging group can tell you all about this lab, contact them at seewhatsinside@cwi.nl.