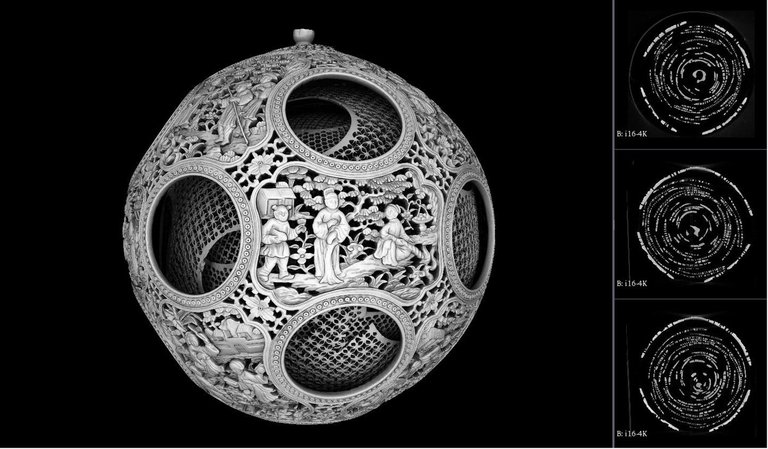

A Chinese puzzle ball is a richly decorated ivory hollow sphere, the size of a tennis ball, with up to twelve other hollow spheres inside. Inwardly the spheres get of course smaller and smaller, but they also become less and less richly decorated. You can move the spheres independently of each other, and the puzzle consists in matching the holes of all the spheres neatly. The spheres are ingeniously crafted from a single solid piece of ivory – a truly artisanal piece of art that must have taken months of work.

Chinese puzzle balls were a status symbol in China three hundred years ago. The Rijksmuseum in Amsterdam has one in its collection and wanted to know exactly how it looks inside without having to open the ball physically. The answer was provided by CWI’s unique FleX-ray scanner. Among other things, the scanner showed that one of the inner spheres had circular grooves, showing exactly how wide and high the blade used by the artist was. It also turned out that the ball was made from African ivory instead of from Asian ivory, which means that there must have been ivory trade between China and Africa centuries ago.